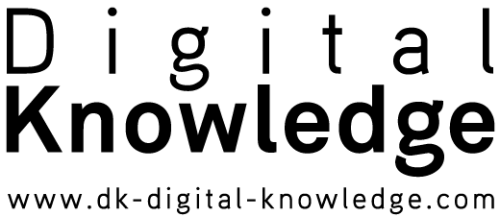

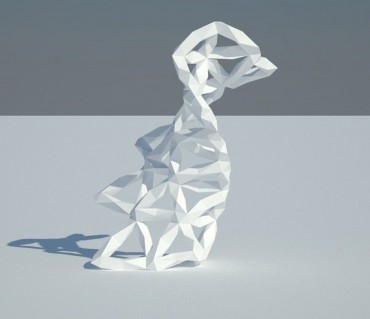

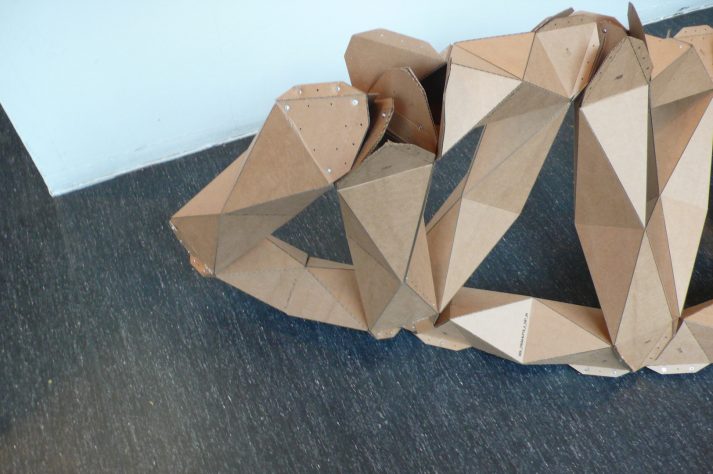

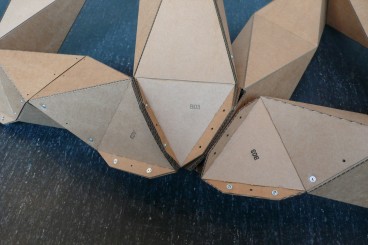

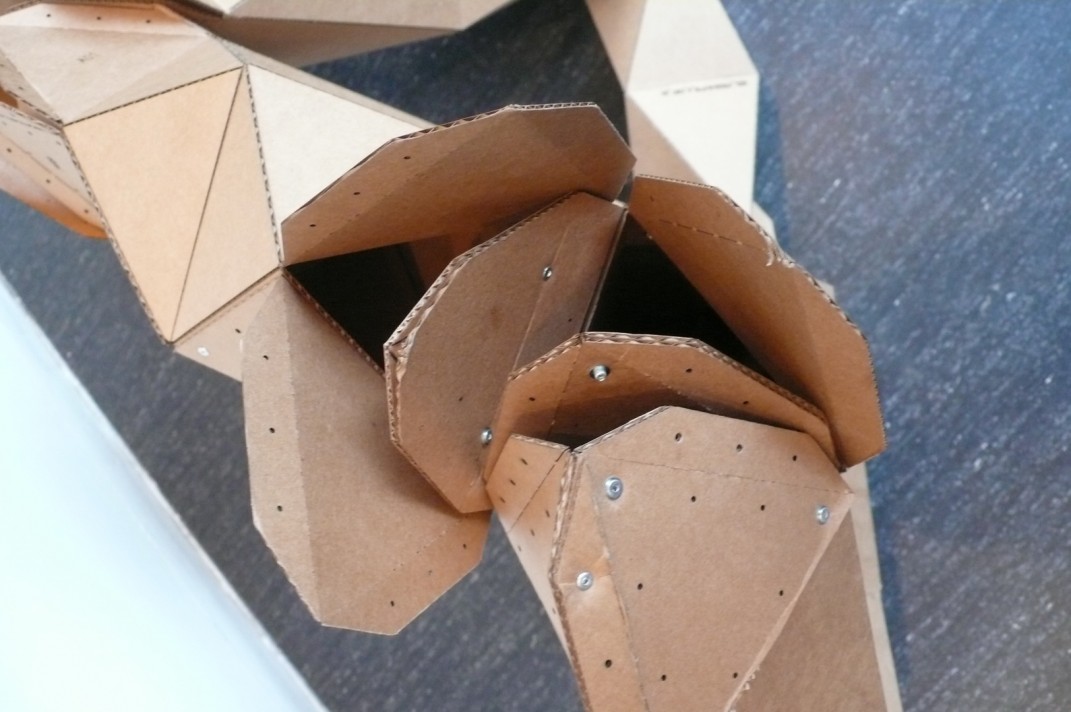

Create a structural module from the analogy with natural tree, this is the objective of this projet. As in nature, joints and bars are combined in one piece. To better achieve this merger a folding process has been studied and developed for a simplified implementation keeping all the structural properties of the object. The digital model used to develop a joint system for overlay surfaces with a mode of instantition in three points. 3D design was done by triangulation of elements designed identically but having their own behavior. The introduction of a third element fits, through the digital model, depending on th escale of the structure offers a large formal freedom.

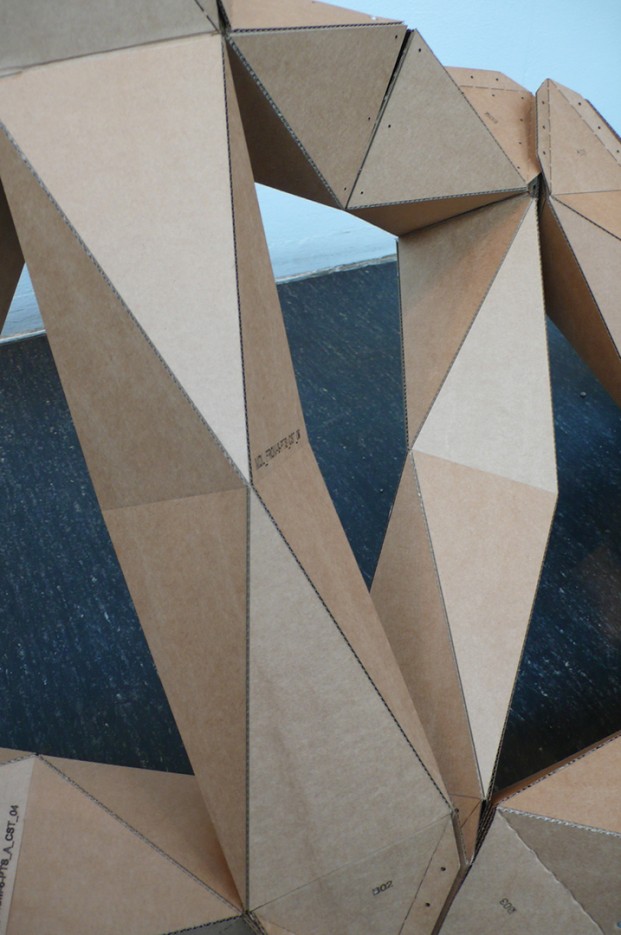

To find a simple, and elegant, sufficient module, performance model was developed mainly in physics, numerical tool for better sizing of elements according to the scale of application of the method. The required accuracy of fit between the elements can be achieved only by laser-cutting. This manufacturing method suggesting a cardboard building as well as in wood or metal, only sheets of material are sufficient. 3D product design itself patterns cutting required for installation. The proposal is a good example of an approach to design and manufacture through a search on the fold as structural potential.

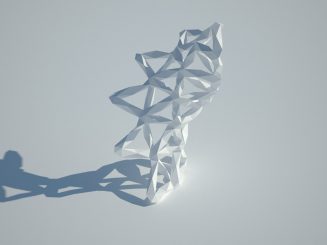

This experiment aimed at developing a three dimensional object, the choice was made on the development of a spiral structure exploiting the full potential of the method. The final draft suggests that such methods would be used for temporary architectures, and leaves the door open to future developments.